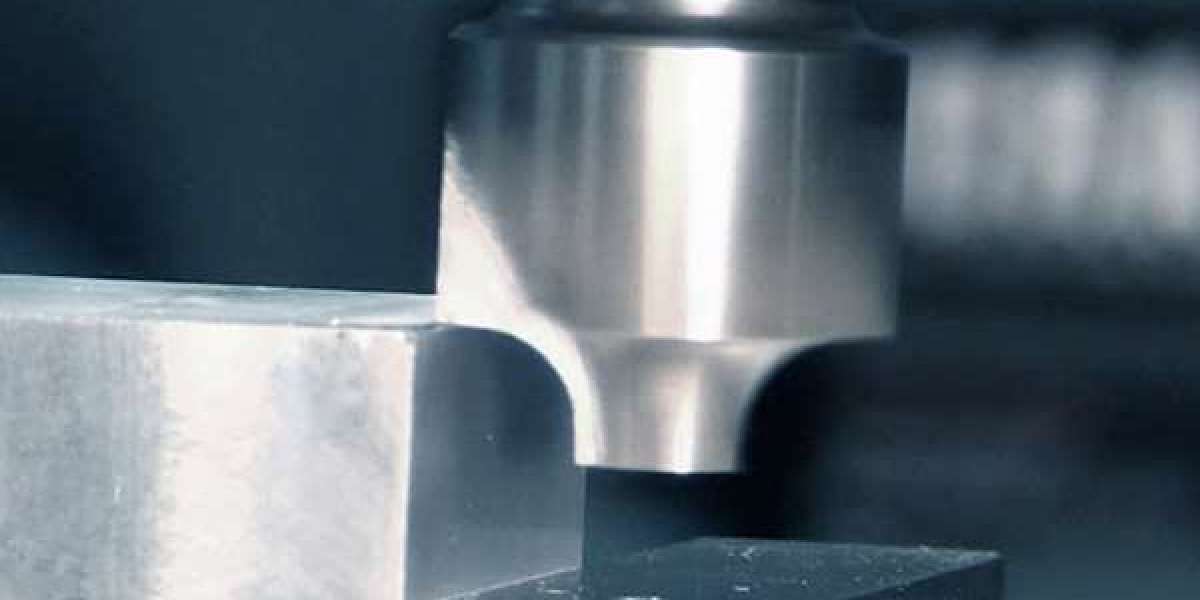

End milling is a versatile CNC machining process that utilizes specialized cutting tools to create intricate shapes and features, making it essential for high-precision manufacturing across various industries.

CNC milling has become a cornerstone of contemporary manufacturing, with end milling being one of its most prevalent methods. This article examines the fundamental aspects of end milling, including its techniques, purposes, and the various types of end mills on the market.Understanding End MillingOverview: End milling uses cutting tools equipped with teeth on both the end and sides, enabling the machining of diverse shapes and features.Uses: This technique is essential for creating slots, pockets, and intricate contours, making it invaluable in various industries.Techniques Employed in End MillingClimb Milling: In this method, the cutter moves in the same direction as the feed, resulting in a smoother finish but demanding a stable setup.Conventional Milling: Here, the cutter moves against the feed direction. While this method is easier to control, it may produce a rougher finish and increase tool wear.Different Types of End MillsFlat End Mills: These are optimal for machining flat surfaces and pockets, offering strong cutting capabilities.Ball End Mills: Suited for creating complex shapes and contours, they excel in finishing operations.Corner Radius End Mills: These combine the benefits of flat and ball end mills, minimizing chipping and enhancing tool longevity.Size FactorsDiameter: The diameter of an end mill influences cutting depth and speed. Smaller diameters are ideal for precise work, while larger ones can handle bulk material removal.Length: Longer end mills can reach deeper features, though they may compromise rigidity.Pros and ConsBenefits:High versatility in producing various shapes.Capability to manufacture high-precision components.Drawbacks:Significant tool wear, particularly with harder materials.Requires careful alignment during setup to avoid inaccuracies.End Milling Versus Other Milling TechniquesEnd milling differs from face milling and slab milling. While face milling targets flat surfaces, end milling is designed for producing intricate details. This distinctive capability highlights the importance of end milling in precision machining.Final ThoughtsGrasping the intricacies of the end milling process, including its techniques, types, and applications, is essential for anyone engaged in CNC milling. By understanding these elements, manufacturers can refine their machining processes and achieve exceptional outcomes.

Планируете заказать аттестат у надежного исполнителя? Заходите!

Планируете заказать аттестат у надежного исполнителя? Заходите!

Как возможно быстро приобрести аттестат в онлайн магазине

Как возможно быстро приобрести аттестат в онлайн магазине

Taste, Explore, Discover the Must-Visit Places in Kuala Lumpur for Every Type of Traveler

By Zahra zaik

Taste, Explore, Discover the Must-Visit Places in Kuala Lumpur for Every Type of Traveler

By Zahra zaik Интернет магазин, в котором возможно заказать диплом университета

Интернет магазин, в котором возможно заказать диплом университета

Ценообразование дипломов - обзор специалистов

Ценообразование дипломов - обзор специалистов

tony marko 7 w

learn more about end milling

https://www.runsom.com/blog/end-milling/