The Evolution of GT Rollers in Geosynthetics: Enhancing Efficiency and Quality

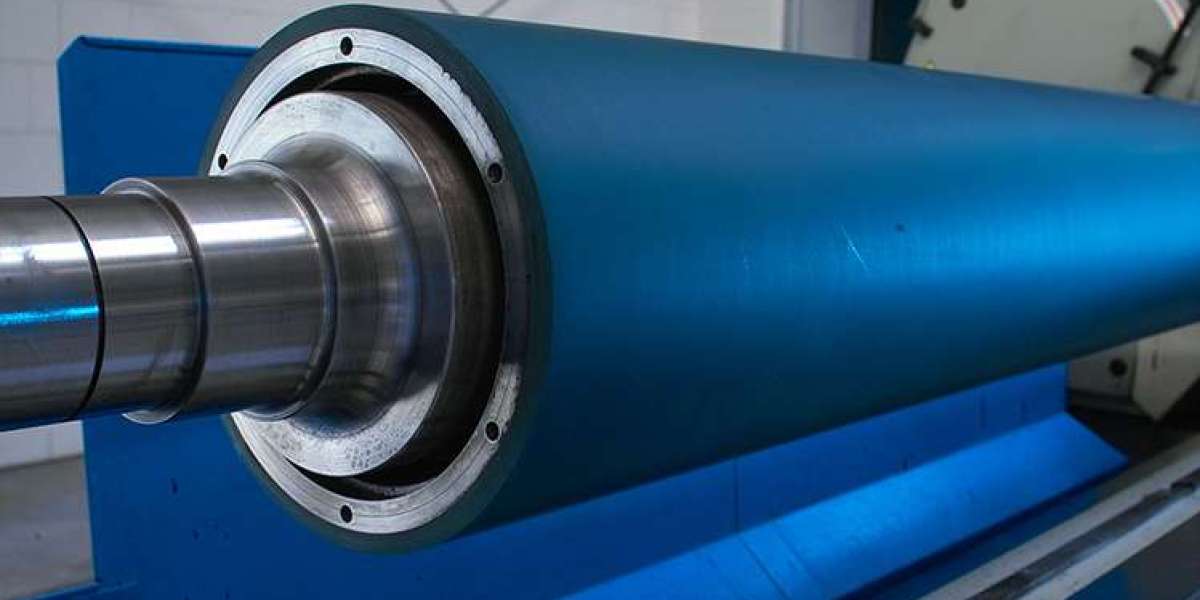

In the realm of geotechnical engineering and construction, the development of innovative technologies continues to revolutionize the efficiency and effectiveness of various processes. Among these advancements, GT Rollers stand out as a pivotal tool in the installation and maintenance of geosynthetics. These rollers, also known as Geotextile Rollers, play a crucial role in ensuring the proper deployment and consolidation of geosynthetic materials, thereby enhancing the durability and performance of infrastructure projects.What are GT Rollers?GT Roller for Geosynthetics http://gtroller.ca/ are specialized machines designed for the installation and compaction of geosynthetic materials such as geotextiles, geomembranes, and geocomposites. They are engineered to exert controlled pressure over large surface areas, facilitating the seamless integration of these materials into the soil or substrate. By employing GT Rollers, construction teams can achieve optimal compaction levels, ensuring the stability and longevity of engineered structures.Key Features and BenefitsPrecision and Control: GT Rollers are equipped with advanced control systems that allow operators to regulate pressure, speed, and direction with precision. This level of control ensures uniform compaction and minimizes the risk of damage to delicate geosynthetic materials.Efficiency in Deployment: Compared to traditional methods, GT Rollers streamline the installation process of geosynthetics. They can handle large rolls of materials efficiently, reducing labor costs and project timelines significantly.Enhanced Project Durability: Proper compaction provided by GT Rollers enhances the overall durability and performance of geosynthetic installations. By eliminating air gaps and achieving optimal soil-to-geosynthetic bonding, these rollers contribute to the long-term stability of infrastructure.Versatility: GT Rollers come in various sizes and configurations to accommodate different project requirements. Whether for road construction, landfill lining, or erosion control measures, these machines can be adapted to suit diverse geotechnical applications.Applications in GeosyntheticsGT Rollers find application across a spectrum of geotechnical projects:Road Construction: Used to compact geotextiles and geocomposites beneath roads, ensuring uniform support and reducing the risk of subsidence.Landfill Liners: Critical in compacting geomembranes and geosynthetic clay liners (GCLs) to prevent leakage and environmental contamination.Erosion Control: Deployed to secure geotextile mats and erosion control blankets on slopes and riverbanks, enhancing stability and soil retention.Future Innovations and TrendsAs technology evolves, the future of GT Rollers in geosynthetics looks promising. Innovations such as automated systems, enhanced material sensors, and integration with digital mapping technologies are set to further improve efficiency and accuracy in geotechnical applications. These advancements not only enhance operational capabilities but also contribute to sustainability efforts by optimizing material usage and minimizing environmental impact.ConclusionIn conclusion, GT Rollers represent a significant advancement in the field of geosynthetics, offering unparalleled precision, efficiency, and durability in material installation and compaction. As infrastructure demands continue to grow globally, these machines will play an increasingly vital role in ensuring the reliability and longevity of geotechnical projects. By embracing and innovating upon the capabilities of GT Rollers, engineers and construction professionals can continue to push the boundaries of what is achievable in geotechnical engineering, paving the way for safer, more sustainable infrastructure solutions.

Планируете заказать аттестат у надежного исполнителя? Заходите!

Планируете заказать аттестат у надежного исполнителя? Заходите!

Как возможно быстро приобрести аттестат в онлайн магазине

Как возможно быстро приобрести аттестат в онлайн магазине

Taste, Explore, Discover the Must-Visit Places in Kuala Lumpur for Every Type of Traveler

By Zahra zaik

Taste, Explore, Discover the Must-Visit Places in Kuala Lumpur for Every Type of Traveler

By Zahra zaik Интернет магазин, в котором возможно заказать диплом университета

Интернет магазин, в котором возможно заказать диплом университета

Ценообразование дипломов - обзор специалистов

Ценообразование дипломов - обзор специалистов