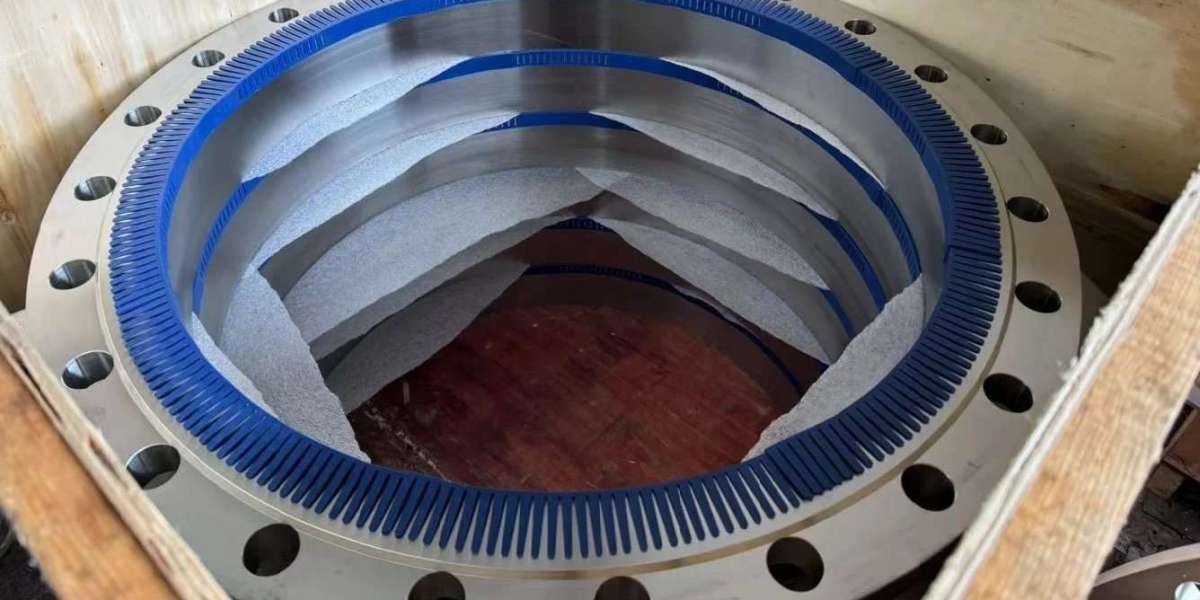

Forging is a manufacturing process that involves shaping metal by applying compressive forces. It is a widely used technique for producing high-quality and durable components for various industries. In this article, we will explore the importance of forging components and its applications.

Forging is a manufacturing process that involves shaping metal by applying compressive forces. It is a widely used technique for producing high-quality and durable components for various industries. In this article, we will explore the importance of forging components and its applications.Improved Strength and ReliabilityOne of the key advantages of https://www.special-metal.com/Products is its ability to produce parts with superior strength and reliability. The process involves heating the metal to a specific temperature and then applying pressure to shape it into the desired form. This compressive force aligns the metal's grain structure, resulting in improved mechanical properties such as increased toughness and resistance to fatigue. Forged components are known for their exceptional strength, making them ideal for applications that require heavy loads or extreme conditions.Precision and VersatilityAnother benefit of forging is the ability to create complex shapes with precision. The process allows for intricate designs and tight tolerances, ensuring that the final product meets the required specifications. This versatility makes forging suitable for a wide range of applications, including automotive, aerospace, oil and gas, and construction industries. Forged components can be found in engine parts, gears, shafts, valves, and many other critical components that require high performance and reliability.Cost-effectiveness and SustainabilityIn addition to strength and precision, forging also offers cost-effectiveness. While the initial tooling and setup costs may be higher compared to other manufacturing processes, the long-term benefits outweigh the investment. Forged components have a longer lifespan, reducing the need for frequent replacements and maintenance. Moreover, the improved mechanical properties of forged parts often result in lower material usage, leading to cost savings in the long run.Furthermore, forging is an environmentally friendly process. Unlike other manufacturing methods that produce a significant amount of waste, forging generates minimal scrap material. The process also requires less energy compared to alternative techniques, contributing to a reduced carbon footprint. As sustainability becomes a growing concern, forging provides a viable solution for industries looking to minimize their environmental impact.ConclusionIn conclusion, forging components offer numerous advantages in terms of strength, precision, cost-effectiveness, and sustainability. The process allows for the production of high-quality parts that can withstand heavy loads and extreme conditions. With its ability to create complex shapes and tight tolerances, forging is widely used in various industries. As technology continues to advance, forging techniques are constantly evolving, further enhancing the capabilities and applications of forged components.China Special Metal Group Limited (CSM), a supplier of steel casting for metallurgical machinery, cement & mining machinery, building material machinery, ceramic industry, forging industry, shipbuilding industry and chemical industry, is dedicated to offering high-quality of steel casting, high-precision machining products and welded fabrications to valued customers all over the world.If you are looking for high-quality forging components solutions, welcome to contact us.E-mail:

[email protected]

Планируете заказать аттестат у надежного исполнителя? Заходите!

Планируете заказать аттестат у надежного исполнителя? Заходите!

Как возможно быстро приобрести аттестат в онлайн магазине

Как возможно быстро приобрести аттестат в онлайн магазине

Taste, Explore, Discover the Must-Visit Places in Kuala Lumpur for Every Type of Traveler

By Zahra zaik

Taste, Explore, Discover the Must-Visit Places in Kuala Lumpur for Every Type of Traveler

By Zahra zaik Интернет магазин, в котором возможно заказать диплом университета

Интернет магазин, в котором возможно заказать диплом университета

Ценообразование дипломов - обзор специалистов

Ценообразование дипломов - обзор специалистов